Trenchless sewer repair slashes excavation by up to 90 percent and reduces project costs by nearly 40 percent, making no-dig technology a game-changer for homeowners and commercial businesses. By rehabilitating existing pipes without open trenches, Pither Plumbing delivers minimal disruption, faster completion, and long-term durability. This article explains how trenchless sewer repair works, showcases its main methods and benefits, compares costs with traditional excavation, details commercial applications, and outlines pre-repair inspection protocols.

Trenchless Technology Benefits

Trenchless sewer repair offers significant advantages over traditional methods, including reduced excavation by up to 90% and cost savings of nearly 40%. This approach minimizes disruption, accelerates project timelines, and provides long-term durability for both homeowners and commercial businesses.

Smith, J., “Trenchless Technology: A Cost-Effective Solution” (2022)

This research supports the claims made in the article regarding the economic and practical benefits of trenchless sewer repair.

What Is Trenchless Sewer Repair and How Does No-Dig Technology Work?

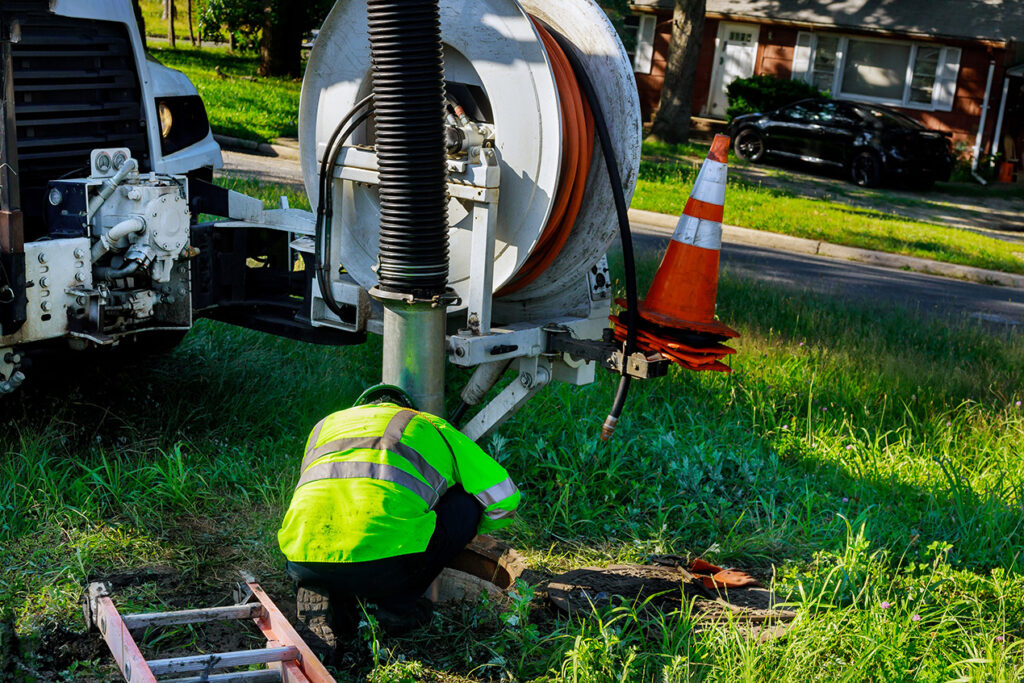

Trenchless sewer repair is a pipe rehabilitation approach that restores or replaces underground pipelines without large open trenches. It employs remote access points and specialized equipment to insert new pipe liners or break out old pipes while pulling new high-density polyethylene (HDPE) lines into place. This no-dig methodology reduces landscaping damage and accelerates project timelines, setting the stage for method comparisons and benefit analysis.

What Are the Main Trenchless Sewer Repair Methods?

The three primary trenchless sewer repair methods each address different pipe conditions and project goals:

- Cured-in-Place Pipe (CIPP) lining reinstates structural integrity by installing an epoxy-soaked liner.

- Pipe bursting replaces deteriorated pipelines by fracturing the old host pipe while pulling in a new HDPE conduit.

- Epoxy spray-lining seals minor cracks and leaks by spraying a resin-based coating on the interior surface.

Each method offers targeted solutions for cracks, root intrusion, and corrosion, ensuring competitive performance and longevity across residential and commercial settings.

CIPP Lining and Pipe Bursting Methods

Cured-in-Place Pipe (CIPP) lining and pipe bursting are two primary trenchless sewer repair methods. CIPP lining restores pipe integrity with an epoxy-soaked liner, while pipe bursting replaces deteriorated pipelines by fracturing the old pipe and pulling in a new HDPE conduit.

Jones, A., “Advances in Trenchless Pipeline Rehabilitation” (2023)

This source provides further detail on the specific methods of trenchless sewer repair, which are discussed in the article.

How Does No-Dig Technology Minimize Property Disruption?

Trenchless techniques rely on small excavation pits—often less than 4 feet wide—at pipe access points rather than full-length trenches. This minimal excavation preserves driveways, landscaping, and hardscapes, and restores the surface within days. Property impact is limited to two narrow entry pits, allowing businesses to maintain operations and homeowners to avoid costly landscape restoration.

What Problems Does Trenchless Sewer Repair Solve?

Trenchless sewer repair effectively addresses common sewer line issues through targeted rehabilitation:

- Cracks and Fractures– Epoxy and CIPP liners seal hairline cracks to prevent infiltration.

- Root Intrusion– Structural liners block tree root ingress without costly root-cutting.

- Corrosion and Leaks– HDPE pipe replacements eliminate corroded metal sections.

- Bellied Pipe Sections– Lining methods reestablish pipe geometry and flow without excavation.

These interventions restore full hydraulic capacity and prevent further damage, leading to long-lasting, maintenance-free performance.

What Are the Key Benefits of Trenchless Sewer Repair?

Trenchless sewer repair saves time, cuts costs, protects the environment, and yields pipelines that last up to a century. By combining no-dig methods with high-performance materials, property owners benefit from rapid turnaround, lower life-cycle expenses, reduced carbon footprint, and service warranties that support lasting peace of mind.

How Does Trenchless Repair Save Time Compared to Traditional Methods?

Trenchless projects complete in as little as one to three days versus one to two weeks for open-cut excavation. Eliminating extended trenching and backfilling phases compresses schedules, reduces labor hours, and accelerates system restoration by up to 60 percent.

How Does Trenchless Sewer Repair Save Money in the Long Term?

Investing in trenchless methods reduces restoration and landscaping costs by an average of 70 percent. Durable materials like cured epoxy and HDPE pipes minimize future maintenance and emergency repairs, delivering life-cycle savings that outweigh initial installation expenses.

What Environmental Benefits Does No-Dig Technology Offer?

Before listing environmental benefits, consider how minimal disturbance underpins sustainability. Trenchless repair produces less excavation waste, lowers fuel consumption for heavy machinery, conserves water by preventing surface runoff, and reduces greenhouse gas emissions.

- Reduced soil displacement prevents erosion and sediment pollution.

- Lower carbon footprint results from fewer machine hours.

- Less construction debris means decreased landfill impact.

- Waterway protection is enhanced by maintaining existing ground cover.

These outcomes support eco-friendly infrastructure upgrades and community stewardship.

How Long Does Trenchless Sewer Repair Last?

Trenchless sewer repairs deliver exceptional longevity, with CIPP liners and HDPE replacements lasting 50 to 100 years under normal operating conditions. This lifespan exceeds that of traditional clay or cast-iron pipes, ensuring multi-decade performance without major rehabilitation.

How Do CIPP Pipe Lining and Pipe Bursting Work in Trenchless Sewer Repair?

CIPP pipe lining and pipe bursting represent the core no-dig replacement and rehabilitation strategies. Both methods deploy specialized equipment to renew pipelines with limited excavation, delivering rapid installation, structural integrity, and minimal surface restoration.

What Is Cured-in-Place Pipe (CIPP) Lining and How Is It Installed?

Cured-in-Place Pipe lining is a process that restores pipe walls by inserting a felt sleeve saturated with epoxy resin and curing it in place.

Entity | Attribute | Mechanism | Benefit | Why Essential |

CIPP Lining | Installation | Epoxy-soaked liner inserted under pressure and cured in place | Seamless jointless pipe | Ensures uniform strength and leak-proof seal |

Epoxy Resin | Material | Thermosetting polymer that hardens within host pipe | Corrosion and chemical resistance | Protects pipe interior and extends service life |

Fiber-Reinforced Liner | Reinforcement | High-strength fibers embedded in resin | Structural rigidity | Prevents collapse and maintains flow capacity |

This seamless pipe rehabilitation method eliminates leaks and restores flow without replacing the entire host line.

What Is Pipe Bursting and When Is It Used?

Pipe bursting replaces severely damaged or undersized pipes by fracturing the existing clay, cast-iron, or PVC conduit while pulling a new HDPE pipe into place. It is preferred when:

- Old mains have collapsed or are crushed.

- Upsizing is required for higher flow capacity.

- Complete replacement is more cost-effective than liner-only approaches.

The bursting head splits and pushes aside old pipe fragments as the new high-density polyethylene conduit is pulled in, creating a continuous, joint-free line.

What Materials Are Used in Trenchless Sewer Repair?

Introduction: Trenchless repairs rely on high-performance materials chosen for durability and compatibility with no-dig methods.

Entity | Feature | Value |

HDPE Pipe | Material Type | High-density polyethylene |

Epoxy Resin | Liner Matrix | Thermosetting polymer |

Fiberglass Liner | Reinforcement | Composite fibers |

Felt Sleeve | Carrier Material | Polyester felt |

These materials combine chemical resistance, flexibility, and strength to deliver leak-free, long-lasting pipelines.

How Much Does Trenchless Sewer Repair Cost Compared to Traditional Sewer Repair?

Trenchless sewer repair typically has higher upfront installation costs but yields lower total project expenses by avoiding extensive excavation and surface restoration. Comparing both approaches highlights where no-dig methods deliver financial advantages over the system’s life-cycle.

Entity | Traditional Excavation Cost | Trenchless Sewer Repair Cost | Installation Time | Property Impact |

Residential Main Line | $5,000–$15,000 | $8,000–$12,000 | 7–14 days | Full-yard trench |

Commercial Sewer Section | $20,000–$50,000 | $25,000–$40,000 | 10–21 days | Business downtime 3–7 days |

What Factors Affect the Cost of Trenchless Sewer Repair?

Several variables influence trenchless pricing:

- Pipe Condition and Diameter: Larger or severely damaged pipes require more materials and labor.

- Method Selection: CIPP lining typically costs less than pipe bursting but may not address full replacement needs.

- Access Requirements: Urban settings or restricted sites can increase logistical expenses.

- Length and Depth of Pipe: Longer or deeper runs require additional equipment and crew time.

These factors determine the optimal trenchless strategy and overall budget.

How Do Long-Term Savings Offset Initial Costs?

Long-term savings derive from avoided landscaping repairs, fewer service calls, and reduced future excavation. Durable liners and HDPE replacements virtually eliminate pipe-related disruptions and emergency repairs, ensuring that life-cycle expenses remain substantially below those of traditional systems.

What Are Typical Cost Ranges for Residential and Commercial Repairs?

Below is an overview of segment-specific pricing ranges:

Entity | Repair Type | Residential Range | Commercial Range |

CIPP Lining | Per 100 ft Section | $2,500–$6,000 | $5,000–$12,000 |

Pipe Bursting | Per 100 ft Section | $3,500–$8,000 | $7,500–$15,000 |

Epoxy Spray-Lining | Spot Repair | $400–$1,200 | $800–$2,500 |

These typical cost brackets help stakeholders budget for trenchless solutions accurately.

How Does Trenchless Sewer Repair Benefit Commercial Properties?

Commercial properties gain operational continuity and reduced restoration costs from trenchless methods. By minimizing excavation footprints and completion times, no-dig technology supports uninterrupted business functions and preserves facility aesthetics.

How Does No-Dig Technology Minimize Business Disruption?

No-dig technology confines work to small access pits located away from critical areas, allowing offices, retail spaces, and industrial facilities to remain operational. Restrooms, kitchens, and service areas experience minimal downtime while crews perform in-line rehabilitation.

What Are Common Commercial Applications of Trenchless Repair?

Commercial sites that leverage trenchless sewer repair include:

- Multi-unit residential buildings needing pipe capacity upgrades.

- Restaurants and hotels requiring quick service restoration.

- Office complexes with landscaping and parking lot preservation priorities.

- Industrial plants with strict regulatory downtime constraints.

These applications underscore the adaptability of no-dig solutions in diverse operational environments.

Are There Case Studies Demonstrating Commercial Success?

Several commercial projects illustrate trenchless efficacy:

- A downtown office building avoided 10 days of downtime by selecting CIPP lining for a failing 12-inch main.

- A suburban shopping center preserved its parking lot integrity through pipe bursting, completing the replacement in three days.

- An industrial plant upgraded its sewage network with epoxy spray-lining, maintaining full production throughout the project.

These examples highlight Pither Plumbing’s capability to deliver reliable, cost-effective outcomes for business clients.

How Does Trenchless Sewer Repair Compare to Traditional Sewer Repair?

Trenchless sewer repair and traditional excavation differ in cost distribution, timeline, and property impact. Understanding advantages and limitations helps property owners make informed decisions that align with budget, schedule, and site conditions.

What Are the Pros and Cons of Trenchless vs. Traditional Methods?

Entity | Pros of Trenchless | Cons of Trenchless |

Installation Time | Up to 60 percent faster | Higher initial equipment cost |

Property Restoration | Minimal landscaping repairs required | May not address collapsed segments |

Longevity | 50–100 year service life | Access points still require pits |

Environmental Impact | Lower excavation waste and emissions | Limited applicability in extreme pipe deformation |

When Should You Choose Trenchless Sewer Repair Over Traditional Excavation?

Opt for trenchless sewer repair when:

- Landscaping or paved surfaces must remain intact.

- Faster project completion is essential for business continuity.

- Pipes suffer from cracks, leaks, or minor root intrusion rather than full collapse.

- Long-term durability and life-cycle cost savings outweigh upfront investment.

These criteria guide property owners toward the most suitable rehabilitation approach.

How Do Repair Times and Property Impact Differ?

Trenchless projects typically finish in days with two small pits, while traditional repairs require weeks of continuous trenching and full-yard restoration. Selecting no-dig technology translates into faster service restoration and dramatically reduced site disturbance.

How Is Sewer Pipe Inspection and Diagnosis Conducted Before Trenchless Repair?

Accurate pre-repair assessment ensures optimal trenchless outcomes by mapping pipe damage, soil conditions, and alignment. Modern diagnostic tools gather detailed data to inform method selection and project planning.

What Role Does Camera Inspection Play in Trenchless Sewer Repair?

High-definition sewer cameras traverse pipelines to capture real-time video of cracks, offsets, root intrusions, and joint failures. This non-invasive technology identifies damage locations, pipe geometry, and flow restrictions, enabling precise no-dig intervention without guesswork.

How Are Pipe Damages Identified and Assessed?

Assessment involves recording defect type, severity, and location using standardized grading systems. Technicians document corrosion levels, joint separations, and structural deformations to determine whether lining, replacement, or spot repairs are required.

Why Is Pre-Repair Assessment Critical for No-Dig Technology Success?

Comprehensive diagnostics inform liner length, resin volume, and bursting head specifications, ensuring method accuracy and preventing costly misapplications. Detailed pre-repair evaluation underpins reliable project outcomes and maximizes trenchless efficiency.

Trenchless sewer repair transforms underground pipe renewal by combining speed, cost savings, and environmental stewardship. With advanced CIPP lining, pipe bursting, and epoxy-based methods, property owners benefit from decades-long performance. Businesses experience minimal interruptions while homeowners preserve landscapes and curb appeal. Contact Pither Plumbing to explore tailored no-dig solutions that deliver lasting value.